Vision

Wind tubrine inspections create thousands of data points, all in different languages – images, vibration readings, heat scans, ultrasonic signals and SCADA Logs. Noos translates all of this into one common language by using AI Agents, so the system can understand what’s really happening inside a turbine, spot problems earlier, avoid repated inspections, cut downtime, and save operators a lot of money. Our goal is to help wind operators to make fast, accurate maintenance decisions every time.

Problem - Too Much Data, No Clarity

Wind turbines are inspected using thermal cameras, IR sensors, vibration sensors, ultrasonic devices, and SCADA systems. Drones and robots now capture higher-quality data than ever, but all these tools speak different “languages”. Nothing connects. Engineers spend days trying to stitch reports together, yet around 80% of the data still goes unused, and operators end up losing $2.5k to $30k per turbine each year through repeated inspections, slow diagnosis, and avoidable downtime.

Solution - Turning Raw Data into Clear Decisions

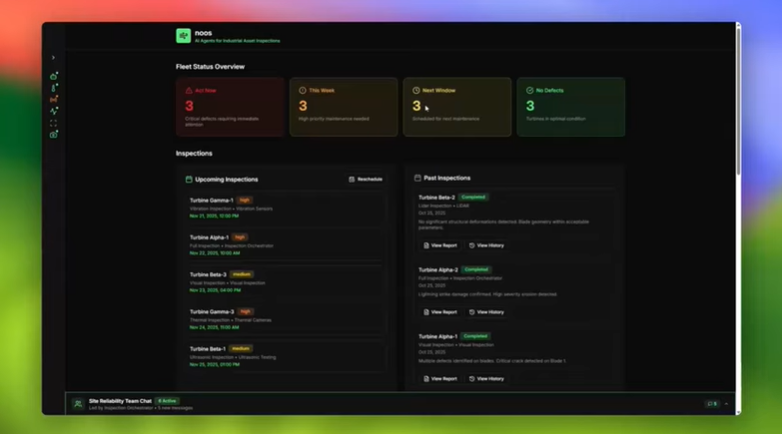

Noos AI automatically analyzes all turbine inspection data from drone images, LiDAR, thermal scans, vibration logs, ultrasonic signals, and SCADA events turning weeks of manual engineering work into seconds. The AI Agents compare all signals together, find hidden correlations humans usually miss, and instantly identify the real root cause. A human engineer might examine 5-10 signals at once. Noos can analyze hundreds of channels in parallel across all sensors. The system generates clear, mobile-friendly maintenance reports that tell operators what’s happening, why it’s happening, and what action to take.

ACCESS DEMO

How It Benefits Wind Operators

Wind operators spend about $60,000 per turbine per year on O&M, with $12,000 going into inspections. Because these systems don’t connect, another $5,000 – $30,000 per turbine is lost annually through duplicate inspections, slow diagnosis, and avoidable downtime.

Noos removes this waste by unifying all inspection data into one intelligent system, speeding decisions from weeks to minutes and preventing repeated site visits. At $1,200 per turbine per year, operators see a 1.5× ROI, save roughly 20% of fragmentation losses, and achieve payback in around 6 months.

© 2026 NOOS