Vision - Human to Autonomous

Heavy industries depend on inspections to keep critical assets safe and operational, yet most inspections remain human-led, manual, and difficult to scale as assets age and systems grow more complex. Noos builds AI inspection agents, and robots are how those agents interact with the physical world. Our vision is to automate ultrasonic inspection by combining robots that can fly, see, move, and touch with AI Agents that interpret signals, reason about asset health, and drive maintenance decisions. Together, they replace human-led inspection with consistent, autonomous systems that scale across industrial assets. Today, Noos delivers a turnkey ultrasonic inspection system: a robotic manipulator that automates probe handling, paired with Noos AI Agents that interpret ultrasonic signals, verify corrective actions, and generate standardised inspection decisions. This forms the foundation for autonomous inspection across heavy industries.

Problem - Ultrasonic Inspection Is a Human Bottleneck

Ultrasonic inspection is still a human-led process. Technicians manually position probes, tune settings, and interpret noisy signals in confined and hazardous environments, making inspection quality highly dependent on individual skill and conditions. Because ultrasonic signals are difficult to reproduce exactly, inspections are often inconclusive. Small variations in probe placement or interpretation lead to missed defects, false calls, and repeated site visits. Results are documented in reports and PDFs, but the underlying inspection data is rarely reused or compared across assets and time. In practice, operators lose thousands of dollars per asset per year through re-inspections, delayed maintenance decisions, and avoidable downtime. As assets age and inspection frequency increases, this human bottleneck does not scale. Inspection becomes slower, riskier, and more expensive turning a safety process into a growing operational constraint.

Solution - Removing the Human Bottleneck

The bottleneck in ultrasonic inspection is human execution and judgment at the moment where consistency and repeatability matter most. Noos removes this bottleneck by shifting execution and decision-making into AI inspection agents embodied in robots. A robotic manipulator performs consistent probe placement and scanning, while Noos AI Agents interpret ultrasonic signals, reason over inspection history and asset context, and verify corrective actions automatically. By standardising inspection decisions across assets and time, the AI Agents eliminate repeat inspections, reduce false positives, and surface early defects before they escalate. For operators, this translates directly into fewer site visits, shorter inspection-to-decision cycles, reduced safety exposure, and materially lower inspection and downtime costs, turning ultrasonic inspection into a predictable, scalable operational function rather than a variable human process.

ACCESS DEMO

Technology - AI + Robotics

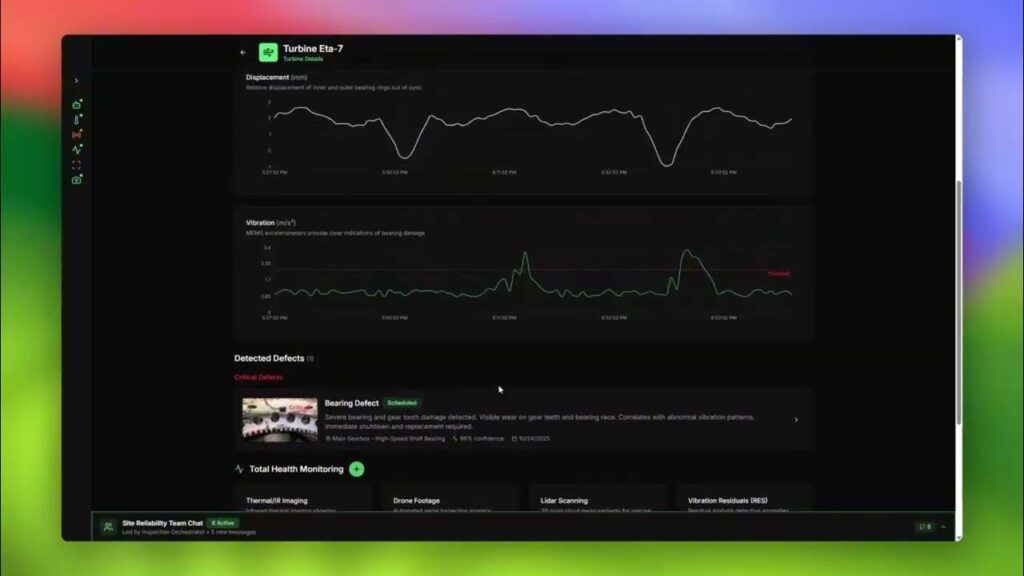

Noos combines Robotics and AI to automate industrial inspections. The robots do what humans physically do today: they move to the asset, place inspection tools, and touch the surface to collect data, even in dangerous or hard-to-reach areas. The AI agents do what experienced inspectors do: they read the inspection signals, compare them with past results, decide if something is wrong, and confirm whether a fix worked. By separating physical work from decision-making and automating both, Noos replaces manual inspection with a consistent, repeatable system that scales.

Noos is designed from the ground up to replace inspection judgment, not just automate data collection.

Industries – Wind Energy & Power Grids, Oil & Gas, Aerospace & Defence, Automotive & Railways

Inspections – Ultrasonic Testing (Bolts, Joints, Structural Components)

© 2026 NOOS